|

|

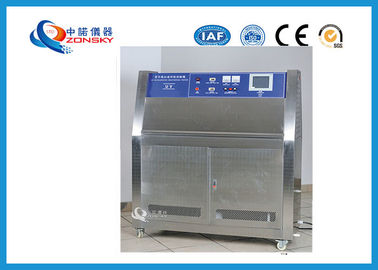

High Precision 220V UV Weathering Chamber Reliable With ISO 9001 Certification

Product Details:

Payment & Shipping Terms:

|

| Material: | SUS 304# Stainless Steel Plate | Outline Size: | 1300 X 500 X 1460 MM |

|---|---|---|---|

| Irradiance Uniformity: | 75 X 150 MM | Power Requirements: | 220V ± 5% |

| Work Space: | About 234 X 353 CM | Environment: | 5 ~ 35 ℃ |

| Highlight: | uv aging test chamber,uv accelerated weathering tester |

||

UV Weathering Test Chamber / UV Testing Machine

1. Application

1.1 The UVA-340 fluorescent ultraviolet lamp is used as the light source to simulate the damage caused by sunlight, rain and dew. UV weatherproof chamber uses fluorescent ultraviolet lamp to simulate the effect of sunlight, and uses condensation moisture to simulate dew. The material under test is placed in a cyclic program of alternating light and moisture at a certain temperature. The accelerated weathering test is carried out to obtain the results of the weathering resistance of the material. UV chambers can be used for several days or weeks to reproduce the hazards of outdoor months or years. Hazard types include: fading, discoloration, loss of light, pink, cracking, turbidity, bubbles, brittleness, strength, decay and oxidation. This machine contains sprinkling device.

1.2 The ultraviolet accelerated aging test chamber can simulate the ultraviolet, rain, high temperature, high humidity, condensation, darkness and other environmental conditions in the natural climate, by reproducing these conditions, merging into a cycle, and letting it automatically complete the cycle number. This is the working principle of UV aging test chamber. In this process, the equipment can automatically monitor the blackboard temperature and the flume temperature. By configuring the irradiance measuring and controlling device (optional), the irradiance can be measured and controlled, so that the irradiance can be stabilized at 0.76W/m2/340nm or the specified set value, and the life span of the lamp can be greatly prolonged.

2. Standards

Conforms with ASTM G 153, ASTM G 154, ASTM D 4329, ASTM D 4799, ASTM D 4587, SAE J2020, ISO 4892, all current UV aging test standards.

3. Specifications

The effective life of the lamp can be about 1600 hours.

(1) Electrical control:

(2) Blackboard temperature and condensing temperature are controlled by controller.

A. The rest basically adopts imported electronic components.

B. Irradiance uniformity: less than 4% (at the surface of the sample).

C. Blackboard temperature monitoring: the standard Pt-100 blackboard temperature degree sensor is used.

D. Accurately control the sample surface temperature during the testing process.

E. Blackboard temperature setting range: BPT 40 - 75℃;

F. The actual maximum temperature limit of the temperature protector inside the machine is 93℃ ±10%.

G. Blackboard temperature control accuracy: ±0.5℃.

(3) Flume temperature monitoring: in the process of cyclic testing, there is a dark condensation process, which requires the chamber to produce a higher temperature of saturated water vapor, when the water vapor encounters the relatively cold surface of the sample, the surface of the sample condenses dew.

A. The sink is located at the lower part of the box body with an electric heater installed.

B. Water tank temperature control range: 40 ~ 60℃

(4) Test box equipped with time controller, range 0 ~ 530H, power failure memory function.

(5) Safety protection device:

A. Temperature overtemperature protection in the box: when the temperature in the box exceeds 93℃±10%, the machine will automatically cut off the lamp and heater electricity

B. The source is supplied and balanced into a cooling state.

C. Low water level alarm to prevent heater from burning.

(6) Standard sample clip:

A. A random number of 75 x 150mm or 75 x 290 mm standard sample clip.

B. The maximum thickness of the sample can reach 20 mm.

C. Non standard size users need to explain when ordering.

D. The sample holder can be loaded directly without sample holder.

E. Standard sample clip 14 row / surface, one row on the back placed the blackboard thermometer.

F. The machine is easy to open.

(7) Box making material:

A. The inner container of the box is made of SUS304# stainless steel plate.

B. The shell is made of SUS304# stainless steel plate.

C. The sample rack is made of stainless steel and aluminum alloy frame to facilitate sample access.

(8) Overview of the whole machine:

A. Size: approx. H1370 * W1350 * D530 mm

B. Weight: about 150 kg

(9) KUV3 host requires working environment:

A. Power requirements: 220V ± 5%, single-phase three wire, 50Hz, 8A, 10A slow melting fuse.

B. Environment: 5 ~ 35℃, 0 ~ 80% RH, well ventilated, clean indoor environment.

C. Work space: About 234 x 353 cm

D. Drainage: A drainage ditch is needed on the floor near the main engine.

In order to facilitate movement, the installation of casters at the bottom of the instrument is fixed.

Then use the U ring to fix the position of the testing machine.

4. Components Chart

|

Controller |

TEMI P990 7 inch |

Korea |

|

Tube |

UVA 340 |

America |

|

Water Pump |

Stainless Steel Mute Corrosion Resistant Pump |

Customized |

|

Temperature Sensor |

VAISALA |

Holland |

|

Heater |

Taiyi Away: |

Taiwan |

|

Circulation Motor |

Dongguan | Taiwan |

|

Power Master Switch |

Tiande | Taiwan |

|

AC relay |

Power Master Switch |

Taiwan |

|

S.S.R |

Fuji |

Janpan |

|

Contact Switch |

Express |

Hongkong |

-

ASTM D4329 UV Testing Equipment / High Performance UV Weathering Test Chamber

-

Tower - Type UV Aging Test Chamber A3 Steel Sheet Spray Treatment Shell

-

PID Controlled UV Testing Equipment / Programmable UV Testing Lab High Accuracy

-

Stainless Steel UV Light Test Chamber 45%~70%R.H Humidity Range ASTM D 4329

-

Box - Type UV Testing Equipment High Precision 0.1 ℃ Temperature Resolution

-

AC 220V 50Hz UV Accelerated Weathering Tester PID Self - Tuning Temperature Control Mode